The use of electrical appliances is very much apparent in our daily lives. At work more specifically it is important to keep people safe and limit any accidents or issues that may arise. In order to do this you need to ensure appliances are tested, and this is where PAT Testing comes in. At IPF Electrical we are specialists in our industry with a number of years of experience. In our latest article we take an indepth look at what is PAT Testing.

The PAT in PAT Testing stands for portable appliance testing. To what degree something is classed as a portable appliance is difficult as there is no definition in current legislation. However, most would class it as ‘any appliance that has a plug and also plugs into a wall outlet’. The word portable sometimes make its a bit misleading, however the 7 main categories that are usually PAT Tested include the following:-

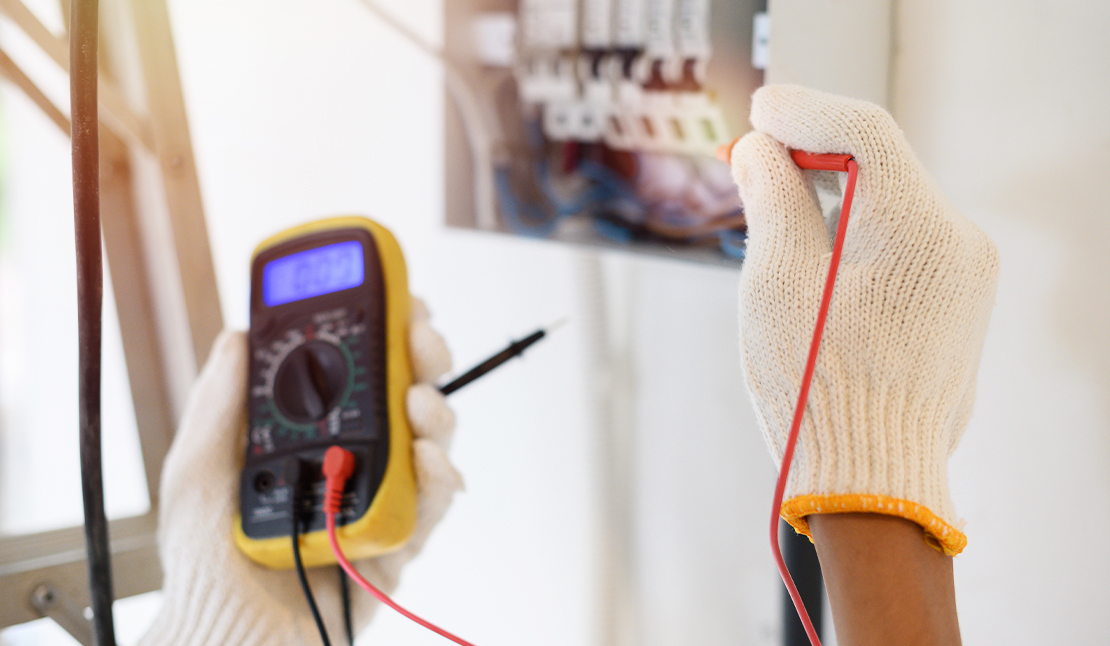

A PAT test is a routine inspection of a variety of electrical equipment to ensure that they are safe to use. The overall purpose of this test is to ensure that there are limited to no electrical accidents which could cause harm or danger to the user. You will be able to identify if an item has been PAT tested as it will be covered by a green sticker that says passed, as well as the date when it was tested and will need to be tested again.

Within the 7 main categories we have listed above, items will also be put into two further categories these being ‘Electrical Class’ and ‘Category’. Both of these are important to determine which items need to be tested. Understanding what both of these areas mean will help to classify products further. In more depth, both of these sections include the following:-

Electrical appliances are broken down in Class 1, 2 and 3. Class 1 is the most dangerous and Class 3 is the least dangerous. The class of the appliance helps to determine whether it firstly needs to be PAT tested and also to what degree it needs. For example, Class 1 appliances need a full PAT Test where Class 3 do not need one at all. To break down the classes further, some of the criteria is as follows:-

As mentioned in the first part of this article, there are 7 categories in which appliances are broken down into. Each category will have a selection of appliances which fall into it. It is from here that each appliance is then put into the classing system as noted above. The electrical specialist will then decide if the item is needing a full PAT Test or none whatsoever. By having this grading structure it is easy for electrical specialists to make informed decisions about what needs to be done.

There is no specific frequency to how long between each PAT test, however items are placed into a grading criteria once again to determine what is going to be best. Regulators do advise that precautions should be taken that are ‘appropriate’ to risk. To determine what frequency should be applied to each appliance they are graded as follows:

To break this down further, the environment in which you work in i.e NHS hospital would mean more regular testing than those in an office block. This is where taking appropriate measures to ensure lowered risk is needed. The class and category of the item are also taken into consideration as discussed above in the previous section.

Alongside looking at ‘appropriate’ precautions, the health and safety executive also recommend that you also take into account the following criteria:-

As you can see the use of PAT testing is very beneficial in many environments. Its primary use as explained thoroughly in what is PAT Testing, is to keep users of a variety of electrical appliances safe. With more of an emphasis placed on health and safety than ever it is vital that you keep up to date with any PAT testing requirements and needs. If you are in need of having PAT Tests completed, or would like some advice then IPF Electrical are more than happy to assist so please do Contact Us.